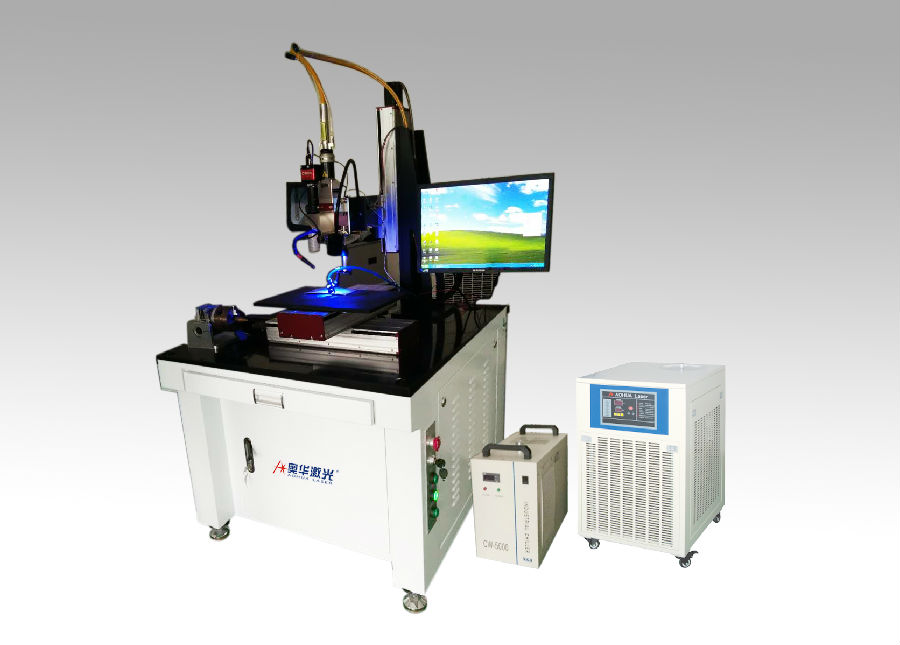

激光连续焊接机

激光连续焊接机

AHL-W1000

焊接特性

laser welding features

1.可将入热量降到最低的需要量,热影响区金相变化范围小,且因热传导所导致的变形亦最低。

2.可降低厚板焊接所需的时间甚至可省掉填料金属的使用。

3.不需使用电极,没有电极污染或受损的顾虑。且因不属于接触式焊接制程,机具的耗损及变形接可降至最低。

4.激光束易于聚焦、对准及受光学仪器所导引,可放置在离工件适当之距离,且可在工件周围的机具或障碍间再导引,其他焊 接法则因受到上述的空间限制而无法发挥。

5.激光束可聚焦在很小的区域,可焊接小型且间隔相近的部件,

6.可焊材质种类范围大,亦可相互接合各种异质材料。

7.易于以自动化进行高速焊接,亦可以数位或电脑控制。

8.焊接薄材或细径线材时,不会像电弧焊接般易有回熔的困扰,而且没有传统弧焊方法中出现的由于弧吹或电极磨损引起的焊 接缺陷。

9.不需真空,亦不需做X射线防护。

10.若以穿孔式焊接,焊道深一宽比可达10:1

11.可以切换装置将激光束传送至多个工作站。

12.工件焊接结束后无需进行大工作量抛光。

1. The heat impact area can be reduced to a minimum, there is the lowest deformation.

2. It can reduce the time required for thick plate welding or f filler metal welding.

3. No need to use the electrode, no electrode pollution or damage concerns.

4. Laser beam is easy to focus, aligned and guided by the optical instrument.

5. Laser beam can be focused in a small area, can be welded small and similar parts,

6. Welding materials can be a wide range of species, but also can be combined with a variety

of heterogeneous materials.

7. Easy to automate high-speed welding, can also be digital or computer control.

8. Welding thin or small diameter wire, not like arc welding like easy to melt the troubled.

9. No vacuum, no need to do X-ray protection.

10. If perforated welding, the weld depth of a wide ratio of up to 10:1

11. The device can be switched to transfer the laser beam to multiple workstations.