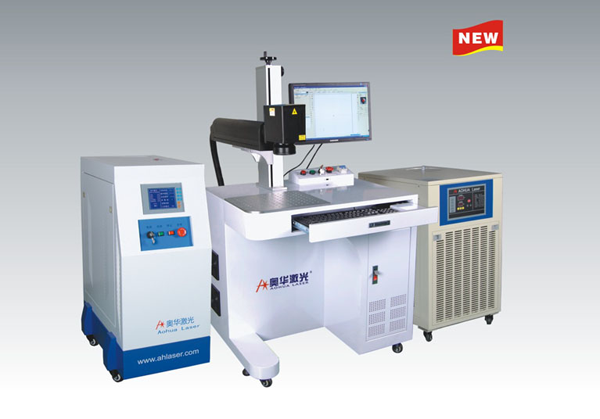

AHL - SW200/SW400/SW600 Galvanometer laser welding machine

AHL ¨CSW200/SW400/SW600 Galvanometer laser welding machine

Application:

1. Galvanometer laser welding machine is mainly applied in areas of high - speed welding, continuous welding and seal welding of relative products including mobile phone shield, metal cell phone enclosure, cellphone battery, phone shells, MP3, MP4 shells, micro motor, jewelry, circuit, sensors, watch, precise machinery,

communication, handicraft, high - end cabinet, elevator accessories, high end furniture ,stainless jug and so on ,It is of high speed and accuracy.

2. Scanning laser welding machine system is suitable for the welding on titanium, nickel, tin, zinc, copper, aluminum, chrome, niobium, gold, silver, and their alloy. Also it is suitble for welding same materials like steel, kovar alloy, and different materials like copper - nickel, nickel - titanium, brass - copper, low carbon steel - copper.

Welding sample for reference:

Specification:

Galvanometer laser weldingmachine | AHL-SW400 | AHL-SW600 |

Max. laser power | 400W | 600W |

Laser wavelengh | 1064nm | 1064nm |

Max energy per pulse | 110J | 130J |

Pulse width | 0.5-20ms | 0.5-20ms |

Continuous laser welding frequency | 1-100HZ | 1-100HZ |

Adjustable facula size | 0.2-2mm | 0.2-2mm |

Control system | Micro -computer | Micro -computer |

Power consumption | ¡Ü12 KW | ¡Ü16 KW |

positioning accuracy | ¡À0.05 mm | ¡À0.05 mm |

Electrical connection | 380V¡À10%/50Hz/40A | 380V¡À10%/50Hz/50A |

Positioning | Red indicator | Red indicator |

Features:

1.The highspeed scanning galvanometer is used to conduct laser positioning with the speed up to 7000mm/second.and the

production efficiency is improved greatly.

2.The digital galvanometer interface with strong anti-interface and better stability.

The special control software with strong function which is easy to operate and compatible with a variety of formats of pic tures and letters.

3.The high-power of cooling system ensures the continuous mass production.