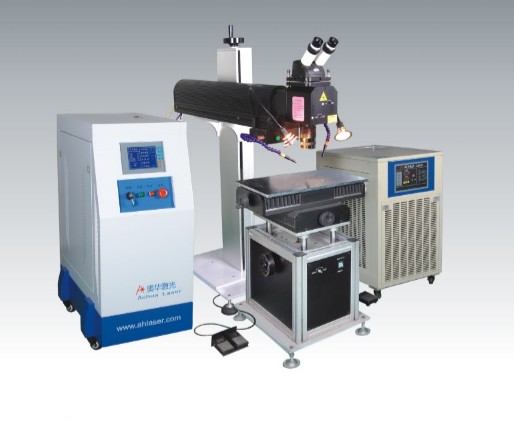

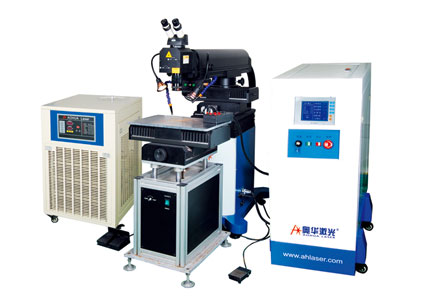

AHL-XW220/400 Laser Mold Welder

1. Cantilevered Laser Mould Welding Machine AHL-XBW220/400 is the sixth generation of laser mould repair equipment developed by AoHua. The optical path of laser can be electically adjusted and controled from ten direction without apdoting the operation way of worktable, which is mainly applied to the outsize, large and medium-size mould repairing and the mould can be placed in carts, forklifts or floor to conduct the repair.

2. It is mainly applicable to mold steel, carbon steel, alloy steel, stainless steel, beryllium copper and copper alloys, as well as such plastic mold, casting mold, forging mold, stamping mold, die casting mold as with extremely hard alloy materials for S136, SKD-11, NAK80, 8407, 718, 738, H13, P20, W302, 2344.

3. It is widely applied in mould manufacturing and molding industries, such as mobile phones, digital products, cars, motorcycles and so on.

1. Laser Mould Welding Machine (Manual Laser Welding Machine) fuses the special welding wire to the damage parts of mould by the hi-heat instantaneously generated by laser, and then firmly fuses and deeply penetrates to the original substrate. After that, it conducts the glossy processing through sparks and grinding in order to repair the mould.

2. It conducts the precision repair for the mould*s blisters, cracks, chippings and wearing parts.

3. The area affected by heat is so small that can*t cause the precision mould deformed.

4. Deep, firm and beautiful welding.

5. Fully dissolved and no repairing trace. Also, there is no depression phenomenon for the joint between convex fuse and substrate.

Specification | AHL-XBW220 | AHL-XBW400 | |

Max. Laser Power | 220W | 400W | |

Laser Wavelength | 1064nm | 1064nm | |

Max. Energy per Pulse | 90J | 110J | |

Laser Welding Depth | 0.1 每 1.0mm | 0.1 每1.0mm | |

Pulse Width | 0.2 每 20ms | 0.2 每 20ms | |

Laser Welding Frequency | 0.5 每 20Hz | 0.5 每 20Hz | |

Range of Adjustable Facula Size | 0.2 每2mm | 0.2 每2mm | |

Laser Welding Wire | 孜 0.2 每 孜0.5mm | 孜 0.2 每 孜0.5mm | |

Power Consumption | ≒ 7KW | ≒ 12KW | |

Electrical Connection | 220V ㊣ 10%/50Hz/40A | 380V ㊣ 10%/50Hz/40A | |

Standard Worktable | 3D manual | 3D manual | |

Positioning | Microscope | Microscope | |

Vertical Distance of Laser | 300mm | 300mm | |

Axial Rotation of Laser | 360o | 360o | |

Horizontal Distance of Laser | Axis Y / XY Electric | Axis Y / XY Electric |

Main Optical Path of Laser

L x W x H:

1590 x 230 x 280mm

Weight:110KG

Worktable

L x W x H:

570 x 530 x700mm

Main Cabinet

L x W x H:

890 x 530 x1030mm

Weight:125KG

Cold Water Tank

L x W x H:

790 x 630 x880mm

Weight:87KG