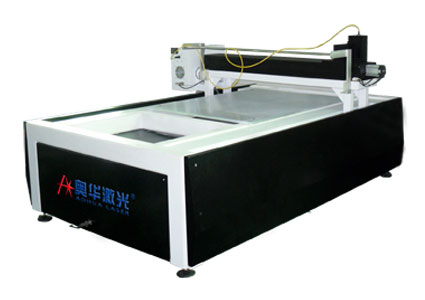

AHLY0404-400 Precision laser cutter

Product Application:

1. Metal, alloy and oxide, ABS, epoxy resin, ink, etc.

2. Widely applicable to electronic components, electrical appliances, jewelries, glasses, hardware, auto parts, communications, plastic keyboards, integrated circuits (IC) and other fields.

Product Features:

The company’s laser cutting punching machine is a kind of automatic device designed by laser and CNC technology, which has high efficiency, low cost, safety, stability and other features. It can cut and punch without touch for metal and nonmetal plates and tubes, especially for the cutting and punching of stainless steel, iron, silicon, ceramic, diamond and other materials. In the metal sheets and hardware industries, the laser cutting punching machine can partially replace the punch and wire cutting. In arts and crafts and decoration industries, the laser cutting machine can be applicable to make art letters and logos. In the electronics industry, it can be used to cut ceramics and silicon sheets. And in the packaging industry, it can be used to cut the mold plates.

1. The control system, controlled by the industrial PC, is easier to operate, and with available automatic programming operation and manual operation.

2. The high precision of punching to drill 0.1mmhole on the thin plate and small cutting seam, and available higher cutting accuracy with the servo system.

3. The open design to make the cutting processing more flexible and convenient for cutting large workpieces.

4. The solid-state laser for the low costs of operation and maintenance.

5. The integrated machine is design with the high efficient protection and emergency devices for the safe and stable operation.

Specification | AHL-C200 | AHL-C400 | AHL-C600 | |||

Max. Laser Power | 200W | 400W | 600W | |||

Laser Wavelength | 1064nm | 1064nm | 1064nm | |||

Cutting Thickness | 0.2 – 1.5mm | 0.2 –3mm | 0.2 –6mm | |||

Min. Cutting Seam | 0.1mm | 0.15mm | 0.2mm | |||

Repetition Accuracy | 0.02mm | 0.02mm | 0.02mm | |||

Cutting Range | Between200mmx200mm–1000mmx1200mmor customized as per the requirement | |||||

Cutting Speed | 1 –600mm/min | 1 –600mm/min | 1 –600mm/min | |||

Power Consumption | ≤ 5KW | ≤ 8KW | ≤ 10KW | |||

Electrical Connection | 220V ± 10%/50Hz/30A | 380V ± 10%/50Hz/40A | 380V ± 10%/50Hz/40A | |||

Control System | PC (adopting CNC2000 System) | |||||

Positioning | Red Indicator (CCD Monitor System Optional) | |||||

Part Name | Net Size(L*W*Hmm) | Paking Size(L*W*Hmm) |

Main Cabinet | 900 x 630 x 1150mm | 970 x 700 x 1230mm |

Cold Water Tank | 790 x 630 x 880mm | 860 x 700 x 950mm |

Main Optical Path of Laser | 1700 x 350 x 350mm | 1770 x 420 x 420mm |